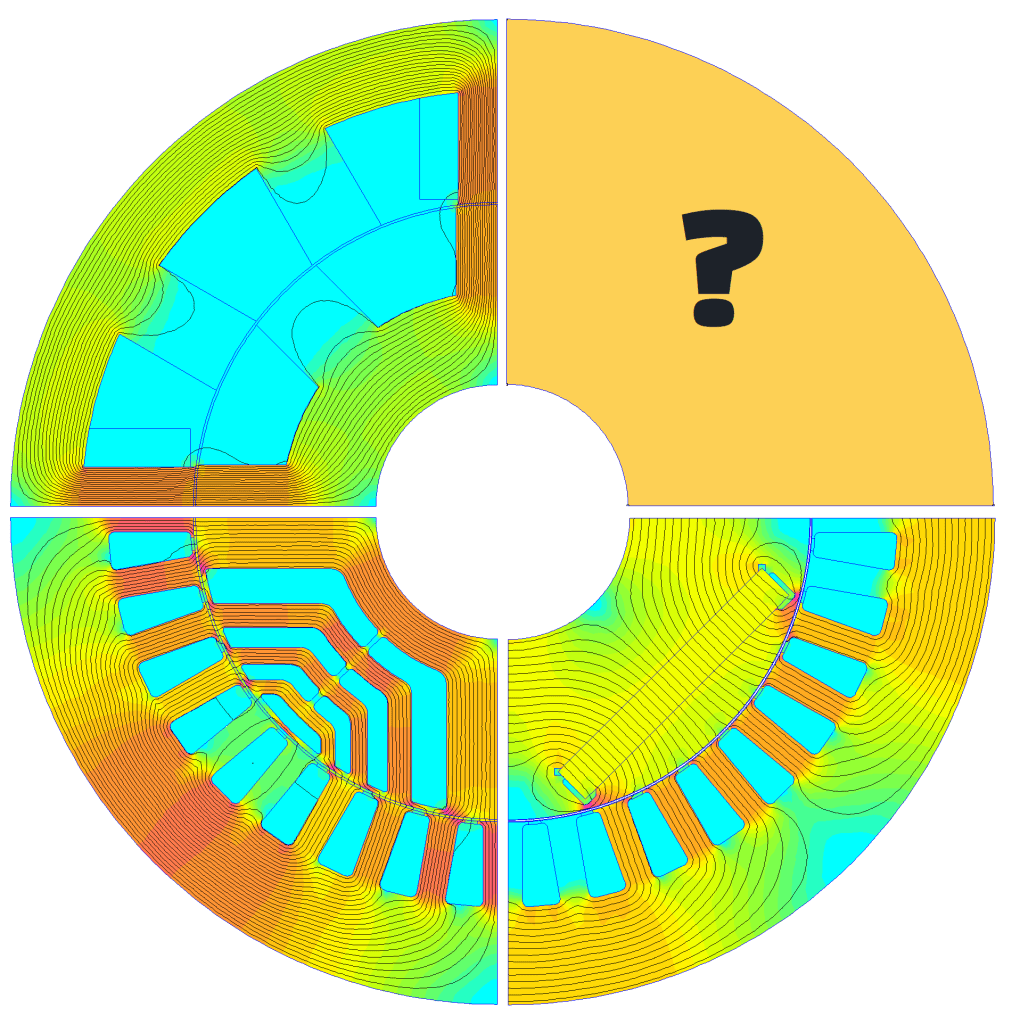

Rotating Machines

The activity of Emodrivex in this field is specialized for the research, development, and design of rotating electrical machines applied in vehicle powertrain, industrial automatization, high-precision robots and actuators. Emphasis is placed on the comprehensive / task specific use of simulation tools, combined with traditional calculation methods. We have the expert background-support necessary for the implementation of special applications and for the handling of special phenomena, including but not limited to the following areas: mechanical design, structural analysis, insulation materials, cooling technology, noise and vibration diagnostics, production support. We maintain an active working relationship with the managers and technological engineers of related manufacturing companies in Hungary.

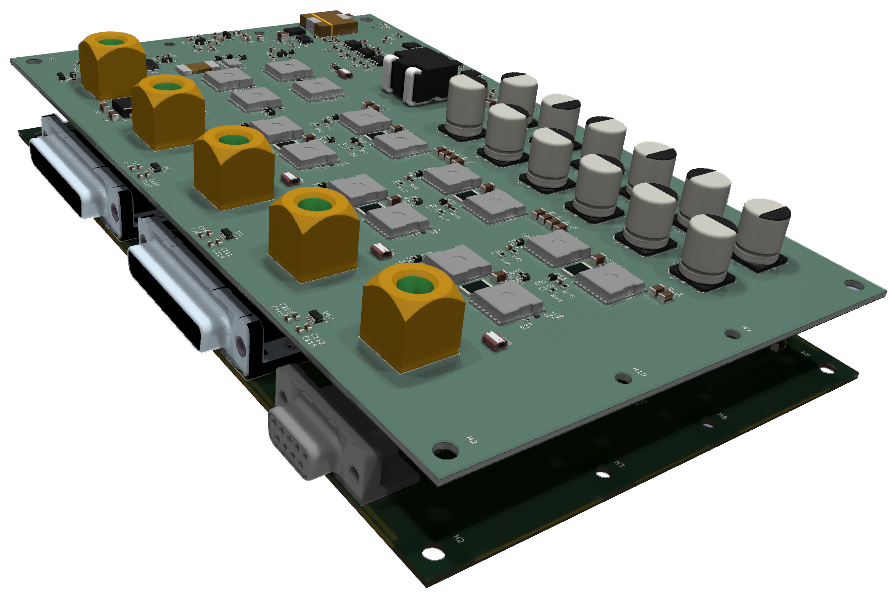

Electrical Drives

R&D engineers of Emodrivex gained hands-on experience related to state-of-the-art high-performance main drives and precision auxiliary drives as well. Our self-developed technologies effectively support rapid prototype validation tasks. We are able to provide engineering service to create unique or custom power electronic devices, design the suitable control structure and carry out its implementation by embedded software development approach.

Development time is minimized by using a model-based software engineering.

Laboratory

Through cooperation agreements with our Partners, we have access to electro-mechanical laboratory facilities in Hungary. Various experimental test conditions can be emulated, e.g. controlled loading, regulated temperature.

Our range of laboratory activities starts straight from the measurement planning, then we manage the test program including on-site validation.

We are capable of high-precision testing of the following electrical equipment within reliable and well-known laboratory conditions:

- only rotating machine (motor, generator)

- drive only (inverter, chopper, frequency converter)

- combined battery-drive-rotating machine

- additional components in case of individual request.

Based on Customer’s needs, we can manage the design and manufacturing of mechanical adapters, support brackets, etc. required for installation.

AI engineering solutions

With the AI Solutions for Engineering business unit we can support our Partners to leverage advanced analytics and artificial intelligence to enhance productivity, innovation, and reliability. By harnessing big data and comprehensive data analysis techniques, we deliver actionable insights that optimize engineering processes and decision-making. Our expertise includes the deployment of cutting-edge neural networks, predictive maintenance models, anomaly detection algorithms, and intelligent digital twins. These solutions enable proactive asset management, optimized operational efficiency, and significant reduction of downtime, driving continuous improvement and competitive advantage in engineering operations.